Surfing the BVI on a Custom Surfboard

by Nancy Read

Surfing is a popular sport in the BVI and I enjoy watching the surfers ride the waves when I walk along Apple Bay. When the ocean swells roll into the island’s north shore each winter, they attract surfers to the island like a magnet.

So, I was curious to learn about a company making custom made surfboards here on Tortola. For many years I had noticed colorful, red, green and yellow signs, posted on the North Shore of Tortola for Island Surf & Sail, a water sport rental business located in Soper’s Hole on the west end of Tortola. Some company signs get weathered and storm damaged and are never replaced…but not so with Island Surf & Sail. Theirs are attractive and colorful, indicative of a creative and evolving business. Operating for over 20 years, Island Surf and Sail, which specializes in water sports equipment sales and rentals, has now branched out into custom made surfboards.

I was curious to learn more about this business that caters to the dedicated surfers that frequent Tortola’s prime surfing spots at Apple, Josiah’s and Cane Garden Bays.

I was delighted to learn that Scott and Debs Hustins were able not only to adapt to life after Hurricanes Irma and Maria in 2017, but that they were able to expand their business and their horizons far beyond what Scott had ever thought possible. You see, they had no choice. Surviving the devastation was an indescribable physical and mental challenge. After realizing that so much of the inventory they had in their shop had been damaged after the roof came off in Maria, they had to come up with a plan, a plan that was creative and economical.

Scott had to devise a way to replenish his destroyed stock of 25 imported surfboards. The cost of purchasing and shipping them to Miami, and then the BVI, would exceed $30,000, money that he didn’t have at the time. Making boards here seemed a good option. Bob Carson who had made custom boards at his shop in Cane Garden Bay was no longer in business. So, Scott decided to contact a surfing acquaintance he knew from Tortola, who had a surfboard supply and board building business in New Jersey.

Scott, who had a background in boat building and in working with fiberglass, boarded a plane and spent two weeks in New Jersey learning a skill which would open new doors and opportunities. He returned to the BVI with five boards, made of a lighter, more flexible, material than had previously been made here. The craft of making surfboards has become a passion for Scott, and every board is a product of his own two hands, from start to finish, and every board is unique, either custom made for a particular customer, or made to supply the rental business.

I was fortunate to visit the shop where this happens and I learned quite a bit about making surfboards. In general, a store will sell you a model of a board. Scott, on the other hand, makes a board to suit the individual and makes different boards for males and females. Women usually like lighter boards as they are easier to carry and to paddle. A custom designed board will suit a customer’s desire, and will be tailor shaped for optimum performance. Scott will create a design from either paint or fabric, which is specifically made for that person. These boards are not the old fashioned “p-u foam,” which was poured and was much heavier, he told me.

First, I was shown the workshop where the boards are shaped. A battery-operated planer was the sound I heard as I first arrived. A tall rectangle of dense styrofoam begins the process. Averaging 7.5 feet in length, it is traced and cut to shape using a hand saw. Wooden templates are laid out to create the desired board shape.

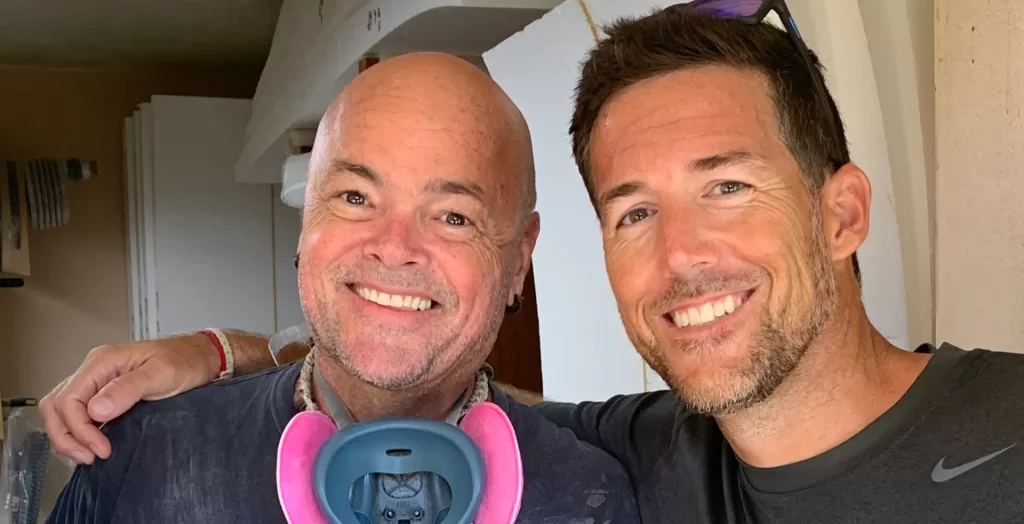

The blank is then brought to thickness: the deck, the rails, the tip and the tail, all have a specific curve to be attained, the nose rocker and tail rocker are continually planed to meet Scott’s satisfaction. Scott wears ear protection with music to enjoy while working.

Once the blank is shaped to perfection, it is relocated from a Scott-made shaping cradle to a resin cradle; the shaping room covered in dust from shaping. This second room is colorful with paint and gallons of liquid products like resins, which I’m told are much less toxic than the old resins. Also, spools of fiberglass are ready to be unrolled and epoxied to the boards. Paint will fade over time, fabric won’t, and Scott has done some serious experimenting with fabrics, enjoying the results. Resin will help to maintain the color of the design over time.

The fin boxes are inserted into the board, one to five fins can be used in three different ways, depending on the surfer’s preference and sea conditions. These are reinforced with fiberglass to provide strength to the board…a fin which breaks is easily replaced; if the board is damaged it is a more costly to repair.

Scott emphasizes that his name, along with the owner’s name, and the West Indies Surfboard logo, is a symbol of his passion on every board. His aim, he says, is to deliver the best suited product and design for each customer. What started out as a way to survive five years ago, has opened a new door for Scott and Deb. Their dependable, devoted staff continues to provide an excellent product in a rental line. They offer paddleboards, kayaks, dive and snorkel gear – even guitars and ukuleles can be rented. The shop is located upstairs, next to Pusser’s at Soper’s Hole Marina.

It is totally refreshing to see a business thrive after experiencing such misfortune five years ago. Times were tough, but they stuck it out with patience and creativity. If the empty rental racks are any indication of their future season, I’d say their time, money and efforts will be duly rewarded this year.

Learn more about West Indies Surfboards at